Organization

More than thirty years experience in field of industrial oil and gas burners having production facility to manufacture wide range of burners.

Over 3000 burners commissioned in various industries. Complete product portfolio for Safe, reliable and energy efficient burner systems.

Energy audits, technical and economical feasibility studies offered for health check- up, improvement or fuel conversion of thermal equipment like boilers, furnaces, ovens and heaters.

Catering to various sectors such as Oil & gas, glass and ceramics, potteries, ferrous & non-ferrous metals, galvanising, foundries and sands, castings, heat treatment, paper, abrasives, textiles, packaging, printing, coatings, automobiles, chemicals, foods, pharmaceuticals, construction, rubber, plastics, home appliances etc.

Installations in applications like Boilers, Heat Treatment Furnaces, Forging, Melting, Die-Casting, Drying and Baking Ovens, Hot Air Generators, Incinerators, etc. Worked in projects for Oil India, LANCO, Ranbaxy, SRF, Hyderabad Industries Limited, Mondeleze India Foods, NCC Ltd., etc.

Burner Design Strength

In house testing facility, where every burner is fire tested before dispatch.

Standardised burner operating parameters, and facility for new development, as per customer's demand.

Robust and reliable burner design.

Incorporates state of art combustion and control technology, for best performance and lowest emission in flue gases.

Made to suit Indian environment and working conditions.

Burners available to suit waste heat recycling. Pressure balanced air gas ratio regulation design is available.

Oxygen trim and automatic air fuel firing rate control is available.

Safe and smooth ignition and accurate firing modulation as per heat demand.

High turndown burners available for low temperature applications.

Low & Medium Temprature Burner

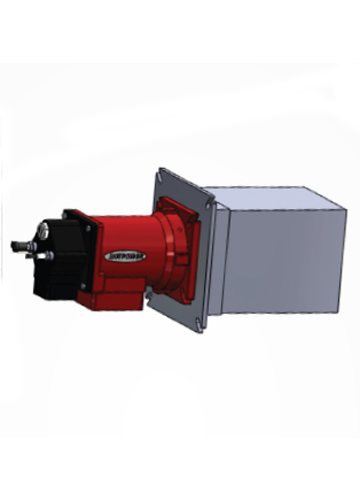

Monoblock Burner

HOTPOWER-FM series burners are compact in construction, energy efficient, simple in design, easy to install and commission. They are generally suitable for low temperature applications (up to 350°C). Several models are available ranging from 2 kg/hr to 60 kg/hr.

Capacity Table

| BURNER MODEL | HEAT OUTPUT | KW FUEL |

|---|---|---|

| FM-10-G | 20-100 | Gas |

| FM-20-G | 40-200 | Gas |

| FM-30-G | 80-300 | Gas |

| FM-40-G | 100-400 | Gas |

| FM-60-G | 150-600 | Gas |

| FM-10-L | 20-100 | Oil |

| FM-20-L | 40-200 | Oil |

| FM-30-L | 80-300 | Oil |

| FM-40-L | 100-400 | Oil |

| FM-60-L | 150-600 | Oil |

APPLICATIONS

Boilers

Textile stenters

Air/Oil/Water heaters Powder/paint oven

Drying and curing Ovens Annealing oven

Small crucible furnaces

Ageing ovens

Roller heating

Roasters, fryers, bakers

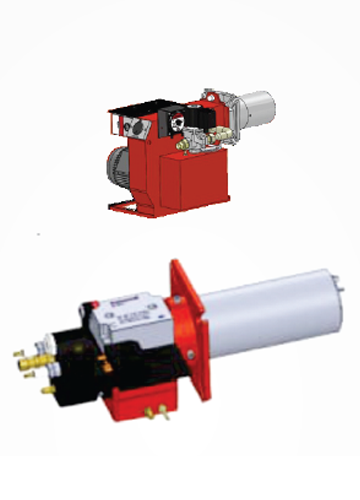

Power Burner

HOTPOWER-FAB series are suited for large industrial applications. The extensive applications on boilers, furnaces, heaters and process plants can be equipped with these versatile burners. They are available for firing range of 60 kg/hr to 1400kg/hr.

Capacity Table

| BURNER MODEL | HEAT OUTPUT KW | FUEL |

|---|---|---|

| FAB-15 | 320-1250l | Oil/Gas/Dual fue |

| FAB-20 | 450-1800 | Oil/Gas/Dual fuel |

| FAB-25 | 875-3500 | Oil/Gas/Dual |

| FAB-30 | 1250-5000 | Oil/Gas/Dual fuel |

| FAB-35 | 1675-6700 | Oil/Gas/Dual fuel |

| FAB-40 | 2100-8250 | Oil/Gas/Dual fuel |

| FAB-45 | 2500-10000 | Oil/Gas/Dual fuel |

| FAB-50 | 2800-11200 | Oil/Gas/Dual fuel |

APPLICATIONS

Melting Furnaces (Aluminum/Brass/ Copper/ Cast Iron, etc.)

Heat Treatment Furnaces (Ageing/Annealing/ Stress Relieving/Tempering Hardening, etc.)

Pressure Die-Casting Forging

Medium & High Temprature Burner

Automatic Furnace Burner

HOTPOWER-FC series burners are rugged in construction, highly reliable as well as energy efficient. They are suitable for high temperature applications (up to 1300°-1400°C). There are several models having firing range of 2 kg/hr to 150 kg/hr.

Capacity Table

| BURNER MODEL | HEAT OUTPUT | FUEL |

|---|---|---|

| FC-5-G | 8-30 | Gas |

| FC-10-G | 20-75 | Gas |

| FC-15-G | 45-180 | Gas |

| FC-25-G | 70-275 | Gas |

| FC-40-G | 115-450 | Gas |

| FC-60-G | 165-650 | Gas |

| FC-100-G | 310-1250 | Gas |

| FC-150-G | 465-1850 | Gas |

APPLICATIONS

Furnaces up to 1450 C

For melting, heat treatment, reheating, hardening, tempering, stress relieving, normalizing, annealing, forging, end heating etc

Rotary furnaces

Hearth/ tunnel furnaces

Box type/tilting furnace

Crucible furnaces

CONVENTIONAL FURNACE BURNER

HOTPOWER-LAP series burners are useful in industrial furnace applications. The burners are very reliable in harsh operating condition, and have very low installation and maintenance cost. This type of burners have been used successfully for last more than 100 years for various high temperature applications. They are available in various capacities ranging from 30 KW to 1,744 KW.

Capacity Table

| BURNER MODEL | HEAT OUTPUT KW | FUEL |

|---|---|---|

| LAP-2 | 70 | Oil/Gas/Dual fuel |

| LAP-3 | 105 | Oil/Gas/Dual fuel |

| LAP-4 | 174 | Oil/Gas/Dual fuel |

| LAP-5 | 291 | Oil/Gas/Dual fuel |

| LAP-6 | 465 | Oil/Gas/Dual fuel |

| LAP-7 | 872 | Oil/Gas/Dual fuel |

| LAP-7A | 1,163 | Oil/Gas/Dual fuel |

| LAP-8 | 1,744 | Oil/Gas/Dual fuel |

APPLICATIONS

Furnaces up to 1450 C

For melting, heat treatment, reheating, hardening, tempering, stress relieving, normalizing, annealing, forging, end heating etc.

Rotary furnaces .

Hearth/ tunnel furnaces.

Box type/tilting furnace.

Crucible furnaces

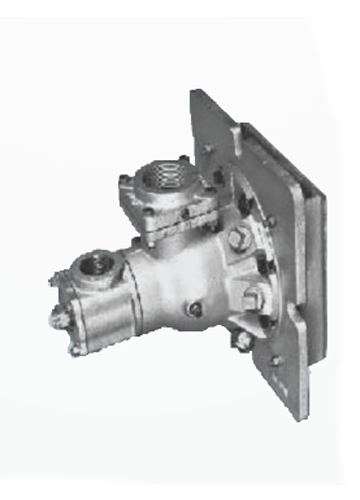

TUBE FIRING BURNER WITH INTERNAL & EXTERNAL BLOWER

HOTPOWER FTM and FTC series burners are available in mono-block and dual-block construction. The burners are suitable for firing inside inside an immersion/ radiant tube. The tube firing burners suitable to replace electrical heaters. These are very easy to install and maintain. The available variants are of 12 KW, 24 KW, 36 KW and 144 KW.

Capacity Table

| BURNER MODEL | HEAT OUTPUT | FUEL |

|---|---|---|

| FTM-1 | 12 | Gas |

| FTM-2 | 24 | Gas |

| FTM-3 | 36 | Gas |

| FTC-12 | 144 | Gas |

| FTC-24 | 288 | Gas |

APPLICATIONS

Powder Coating Oven

Paint Booths

Oil Fryer

Pre-treatment tanks Galvanizing

Tank Heating

Pre Treatment

Heat Treatment Furnaces

Flare Burner

HOTPOWER Flare burners are suitable for burning waste/flare gas from stack. A suitable automatic pilot burner should be installed for reliable ignition and stable burning. There is only one standard model, having a pipe diameter of 4". It has long life cycle and long maintenance intervals.

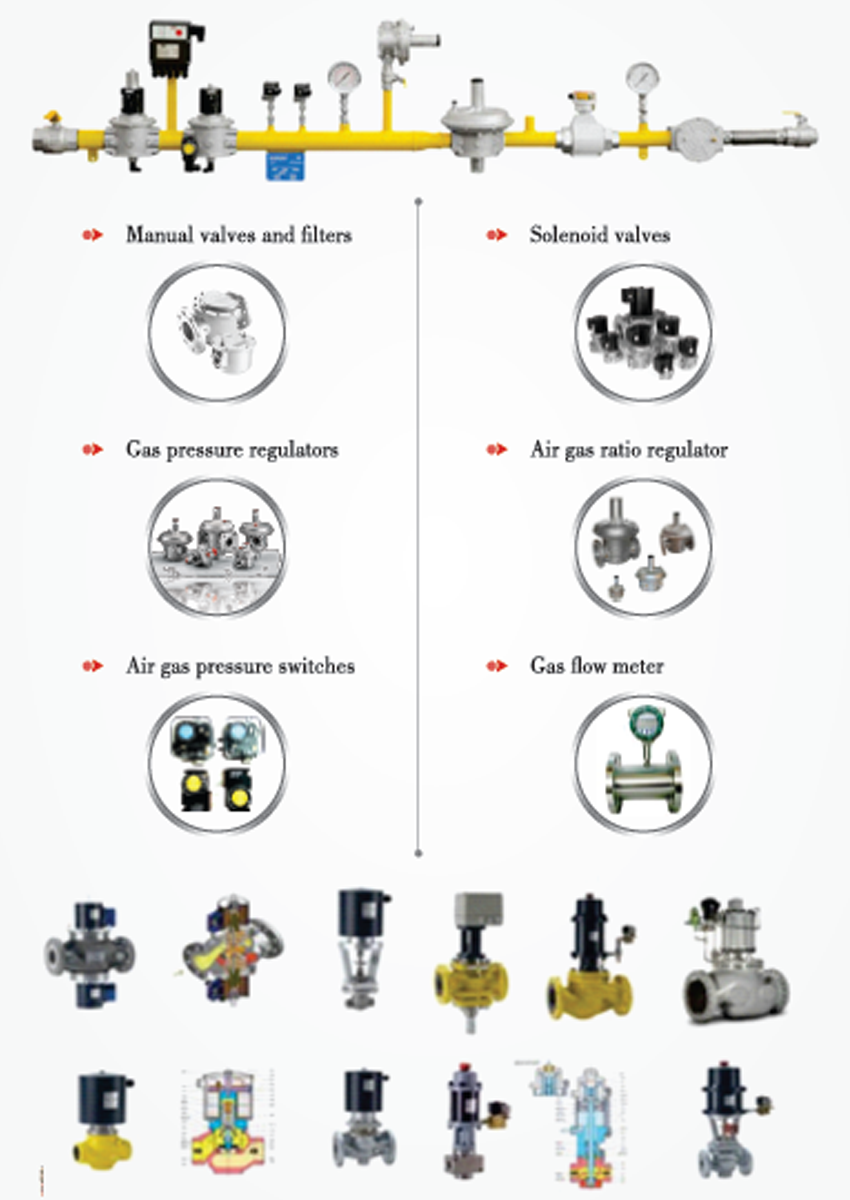

Gas Train Assembly and Component